- Home

- Importance of Quality Control in Pipe Production

Importance of Quality Control in Pipe Production

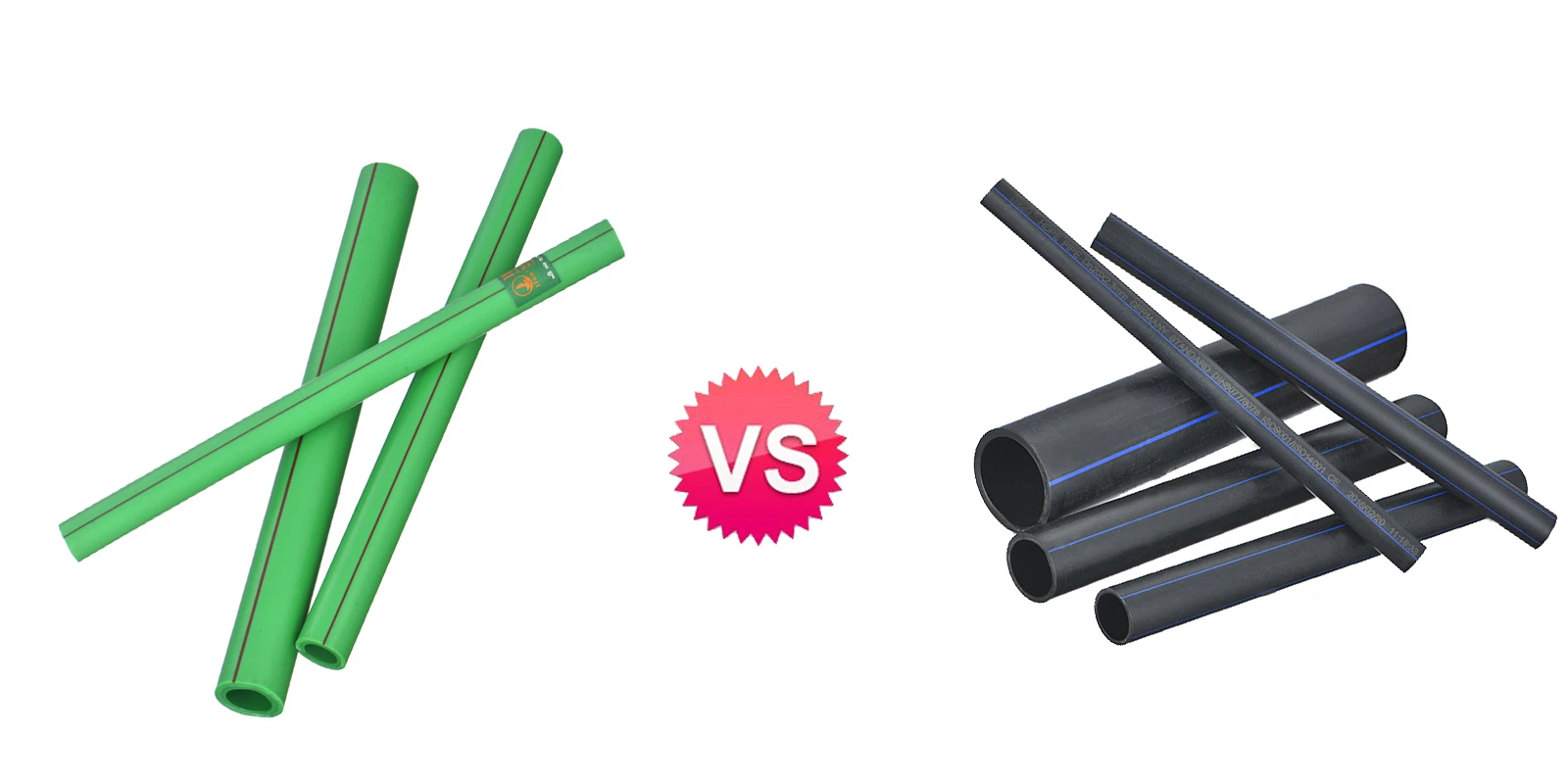

Quality control in pipe production plays a critical role in terms of both the efficiency of production processes and the durability and reliability of the pipes produced. Pipes, which have a wide range of uses from infrastructure projects to industrial facilities, from energy systems to residences, must be produced in accordance with the standards required by the loads they carry and environmental conditions. Therefore, each quality control step carried out in the production process is of great importance for both the manufacturer and the end user.

Quality control processes start from the very beginning of production. The physical and chemical properties of the raw materials used are the basic elements that determine the durability and performance of the pipe. The purity, density and workability properties of the raw materials are meticulously analyzed. Production begins by selecting materials that meet quality standards.During production, the dimensions, wall thicknesses, surface smoothness and mechanical strength of the pipes are constantly checked. These controls, which are carried out with the help of automatic measuring devices and sensors, provide high precision while minimizing human error. In addition, specific features such as the resistance of the pipes to heat, pressure and chemical effects are tested and a conformity assessment is made.

Quality control performed at the final stage of production verifies that the pipes comply with all standards and customer requirements. Hydraulic tests, leakage tests and mechanical strength tests performed during this process allow us to predict how the pipes will perform under field conditions. Products that do not comply with the standards are separated from the production line and reprocessed or destroyed.

Quality control optimizes not only product quality but also the sustainability and environmental impacts of production processes. These processes, which reduce waste, increase energy efficiency and encourage environmentally friendly production methods, enable companies to stand out in market competition.

Quality control in pipe production is the key to offering high-performance and reliable products. Thanks to these meticulously carried out processes, pipes have superior features in terms of long-term use, safety and customer satisfaction. Quality control practices allow manufacturers to meet industry standards as well as fully respond to customer needs.

News

Let You Be the First to Know about Our News and Announcements.

Your Email Address

.jpg)