- Home

- The Future of Pipe Manufacturing

The Future of Pipe Manufacturing

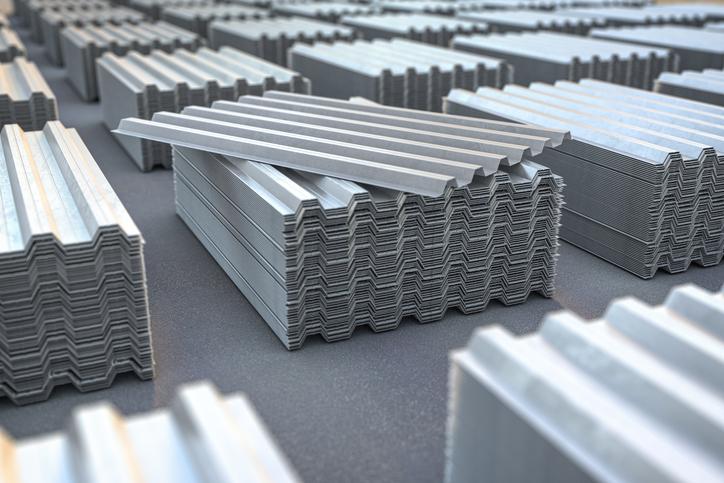

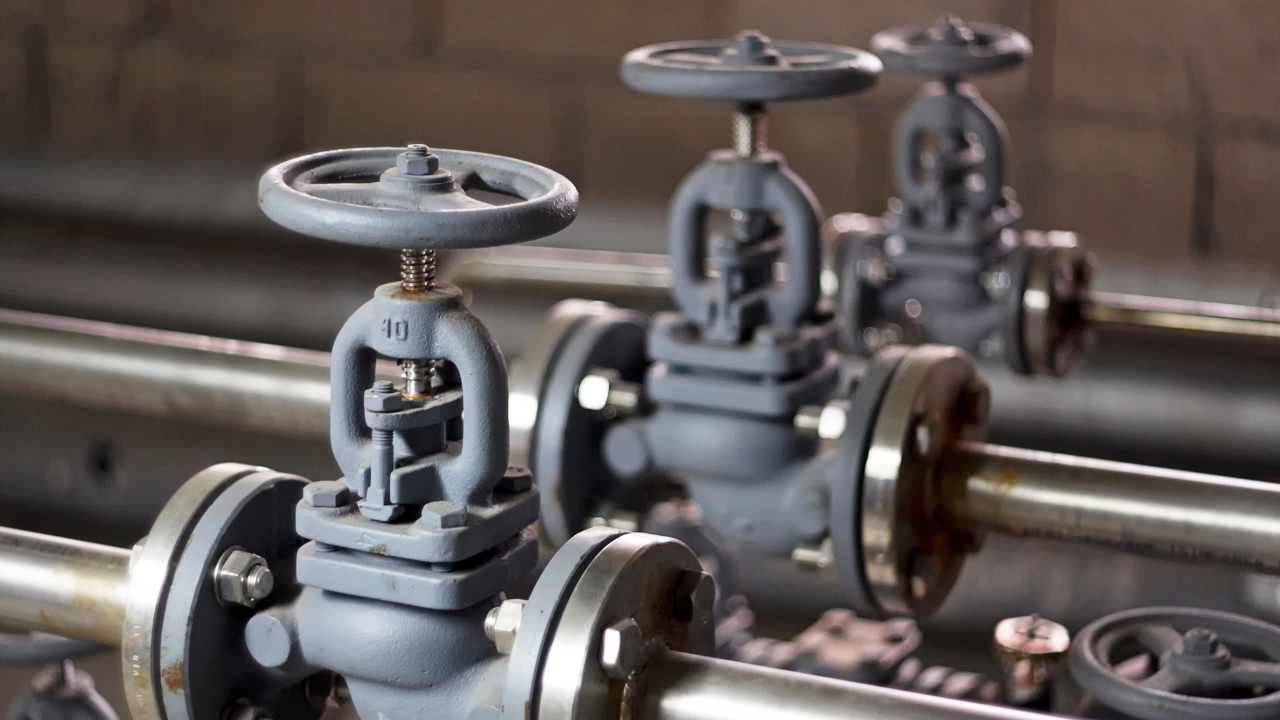

Pipe production is a critical sector that is the backbone of industrial infrastructure. Pipes used in areas such as construction, energy, water supply, natural gas and sewage play a major role in ensuring sustainable life in the modern world. The future of pipe production is shaped in line with technological advances, environmental factors and industrial needs.

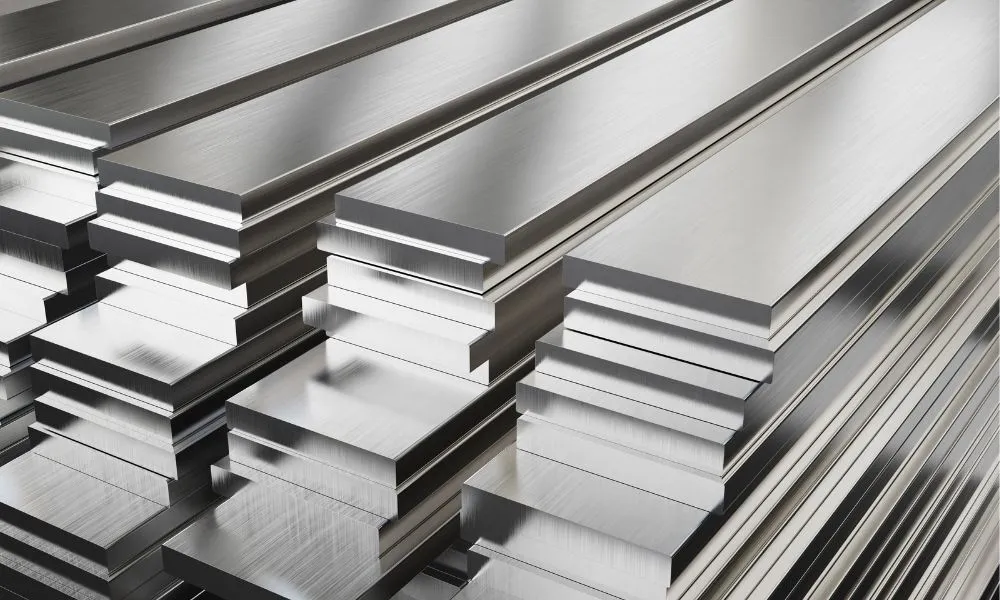

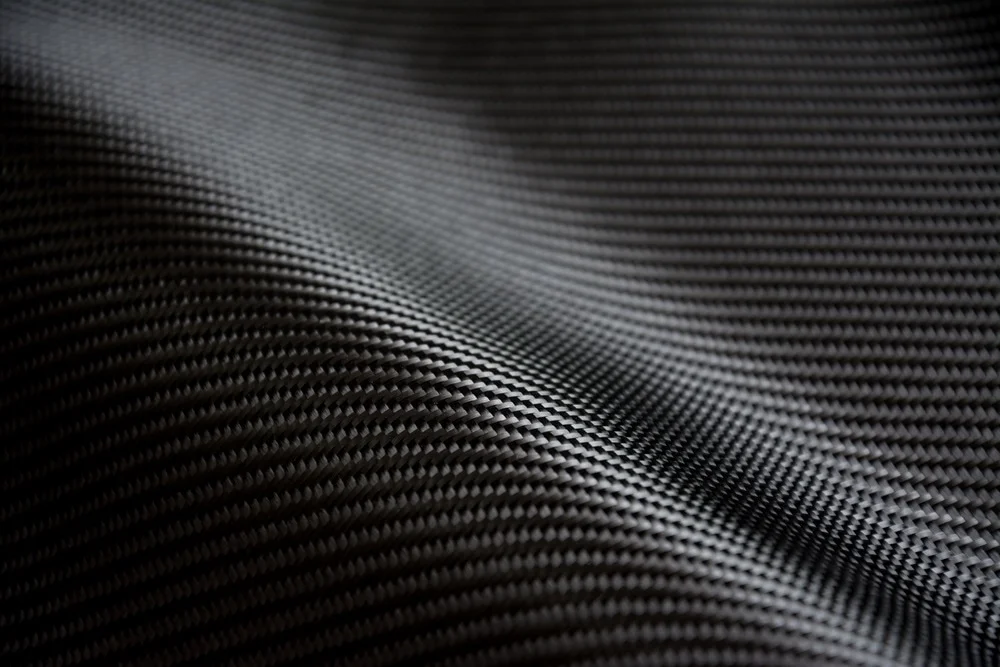

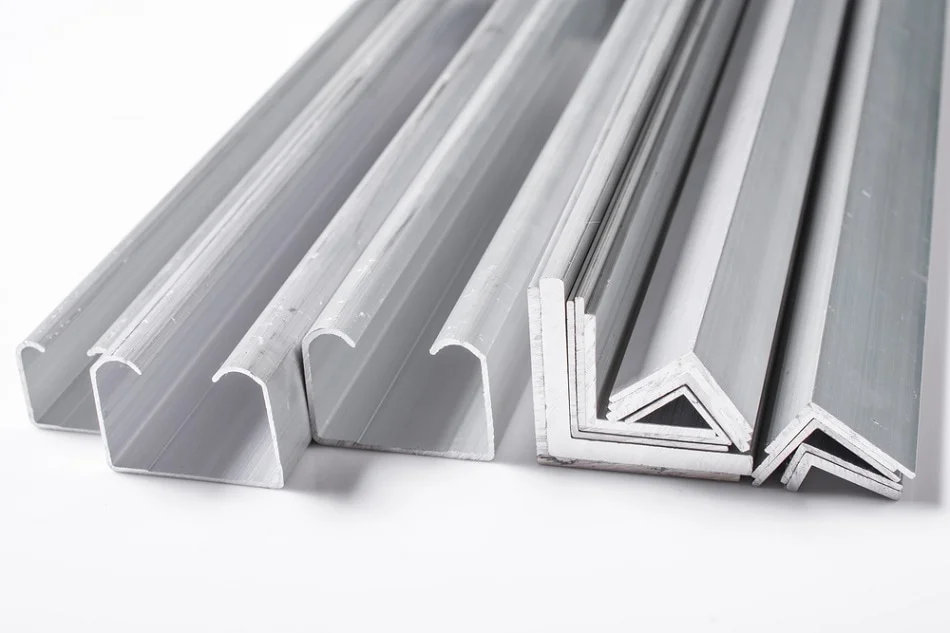

Technological developments are creating a significant transformation in pipe production. In particular, increasing automation in production processes increases efficiency and quality, while also reducing costs. Manufacturers are starting to use advanced materials to produce more durable and long-lasting pipes. These materials include polymers, composite materials and new generation steel alloys. Such materials make pipes lighter, more durable and more environmentally friendly.

In addition, with the increase in environmental awareness, interest in sustainable production methods is also increasing. Pipe manufacturers are trying to reduce their impact on nature by using recyclable and environmentally friendly materials. The integration of renewable energy sources into production processes reduces the carbon footprint in pipe production and enables the emergence of more environmentally friendly products.

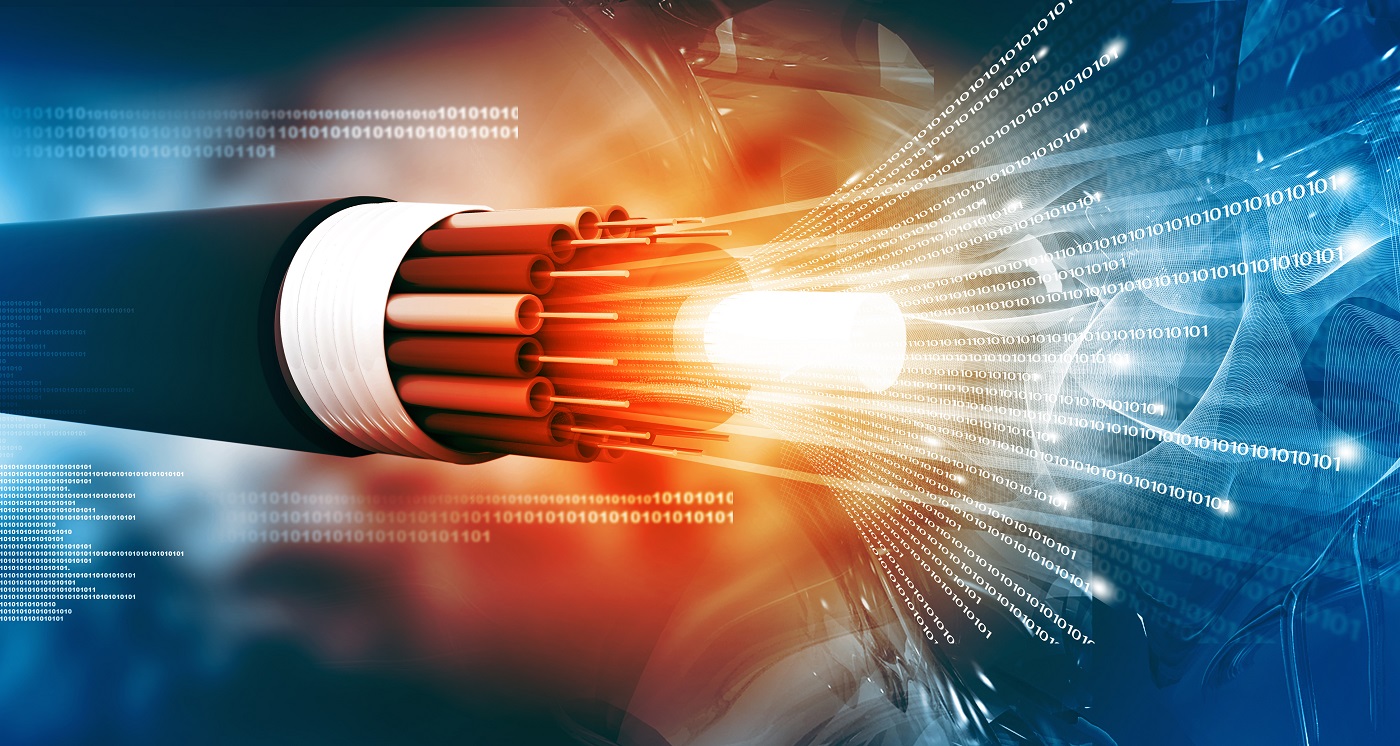

The future of pipe production is also linked to smart infrastructure systems. IoT (Internet of Things) technologies will revolutionize the monitoring and management of pipe systems. Smart sensors and monitoring devices constantly monitor parameters such as pressure, flow rate and temperature in pipelines and detect abnormal situations. In this way, problems that may occur in pipelines are detected in advance, and maintenance and repair operations become more efficient.

In addition, the impact of digitalization in pipe production is also growing. 3D printing technologies offer great advantages, especially in prototype production, and enable pipe manufacturers to develop new designs more quickly and flexibly. In addition, such technologies allow for less waste in production processes and a more efficient production model.

The future of pipe production will be shaped by the integration of innovative technologies, environmentally friendly production methods and smart infrastructure systems. This transformation will both increase industrial efficiency and minimize negative impacts on the environment. In the coming years, these developments in pipe production will ensure that infrastructure projects are more durable, sustainable and efficient.

News

Let You Be the First to Know about Our News and Announcements.

Your Email Address

.jpg)