- Home

- Innovative Pipe Systems: Differences Between HDPE and PPR Pipes

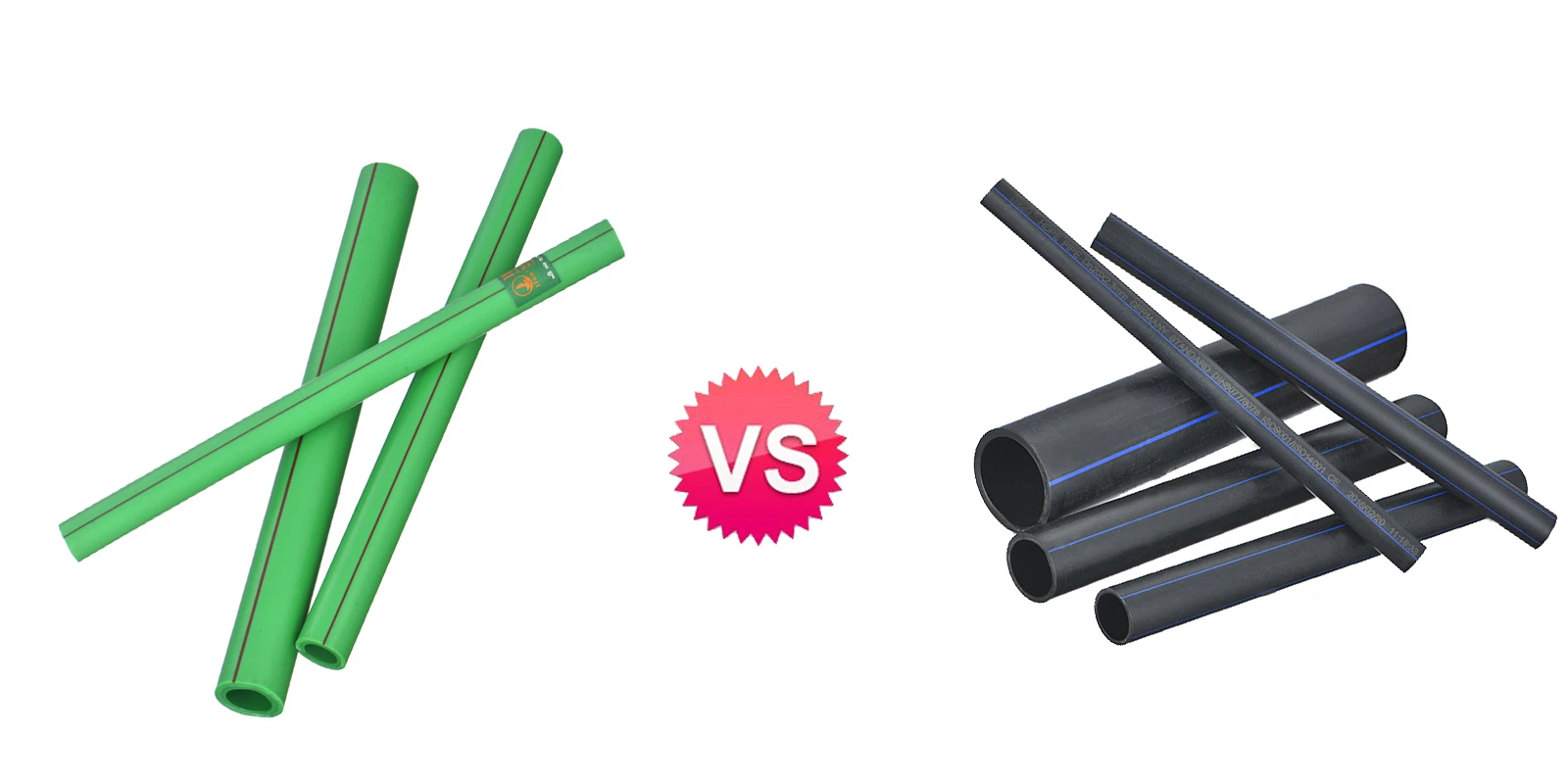

Innovative Pipe Systems: Differences Between HDPE and PPR Pipes

Pipe systems play a critical role in the transportation of water, gas, wastewater or other liquids. The safety, efficiency and longevity of these systems depend on the pipe materials used. In recent years, innovative pipe systems such as HDPE (High Density Polyethylene) and PPR (Polypropylene Random Copolymer) have attracted attention with their various advantages. Both types of pipes offer different features and provide solutions for specific needs.

HDPE Pipes:

HDPE pipes are produced from high-density polyethylene material and are generally used in the transportation of water, gas, wastewater and industrial liquids. One of the biggest advantages of HDPE pipes is that they offer low weight and high flexibility along with excellent chemical resistance. These features allow the pipes to be transported over longer distances and to be easily installed. In addition, HDPE pipes are extremely resistant to mechanical effects such as impact and abrasion.

• Durability and Flexibility: Thanks to their high flexibility, HDPE pipes adapt to different ground conditions and are not affected by earthquakes or soil movements.

• Chemical Resistance: Resistant to most acidic and basic liquids, making them a safe option in industrial applications.

• Long Life: Since they are not affected by corrosive effects, HDPE pipes provide long-term use and their maintenance requirements are quite low.

PPR Pipes:

PPR pipes are produced from polypropylene random copolymer material and are especially preferred in hot and cold water systems. PPR pipes are known for their temperature resistance and resistance to high pressure. Another advantage is that their connections can be made by fusing, which provides sealing in pipelines. PPR pipes are widely used especially in drinking water and heating systems.

• Temperature Resistance: PPR pipes have the capacity to carry hot water and can withstand up to 95°C.

• Sealing and Safety: Connections made by welding method increase sealing and provide safe use.

• Hygienic Properties: PPR pipes used in drinking water systems are materials that do not harm human health and are resistant to biological pollution.

HDPE and PPR Pipe Differences:

The main differences between HDPE and PPR pipes are based on their areas of use, material properties and durability criteria. While HDPE pipes are generally preferred in outdoor applications, especially in underground water transmission systems, PPR pipes are more suitable for indoor use, especially used in drinking water and heating systems.

The flexibility and chemical resistance of HDPE pipes make them especially suitable for industrial and infrastructure projects. PPR pipes, on the other hand, can be used safely in water and heating systems for many years with their temperature resistance and fusion properties.

As a result, both types of pipes offer their own unique advantages. Choosing the right pipe according to the area of use and needs directly affects the efficiency, safety and long life of the system.

News

Let You Be the First to Know about Our News and Announcements.

Your Email Address

.jpg)