- Home

- Methods to Ensure Corrosion Resistance and Long Life of Steel

Methods to Ensure Corrosion Resistance and Long Life of Steel

Steel is a material used in many sectors with its strength and durability. However, when exposed to environmental factors, corrosion can negatively affect the durability and lifespan of steel. Corrosion causes the steel surface to oxidize and weaken, and this poses a major problem especially in industrial applications that require long-term use. Fortunately, there are many effective methods to increase the corrosion resistance of steel and extend its life.

Effects of Corrosion on Steel

Corrosion usually occurs as a result of steel reacting with oxygen and moisture. This process causes rust on the surface of the material and weakens its structural integrity over time. Steel structures, especially those exposed to sea water, chemicals and acidic environments, have a higher risk of corrosion. This situation requires taking different precautions depending on the usage area of the steel.

Methods to Increase Corrosion Resistance

1. Use of Stainless Steel

Stainless steel provides natural resistance to corrosion thanks to the chromium element added to its alloy. Chromium creates a thin and passive oxide layer on the steel surface, preventing oxygen and moisture from reaching the inner surface. This feature makes stainless steel an ideal material in the food, healthcare, energy and chemical industries.

2. Galvanizing

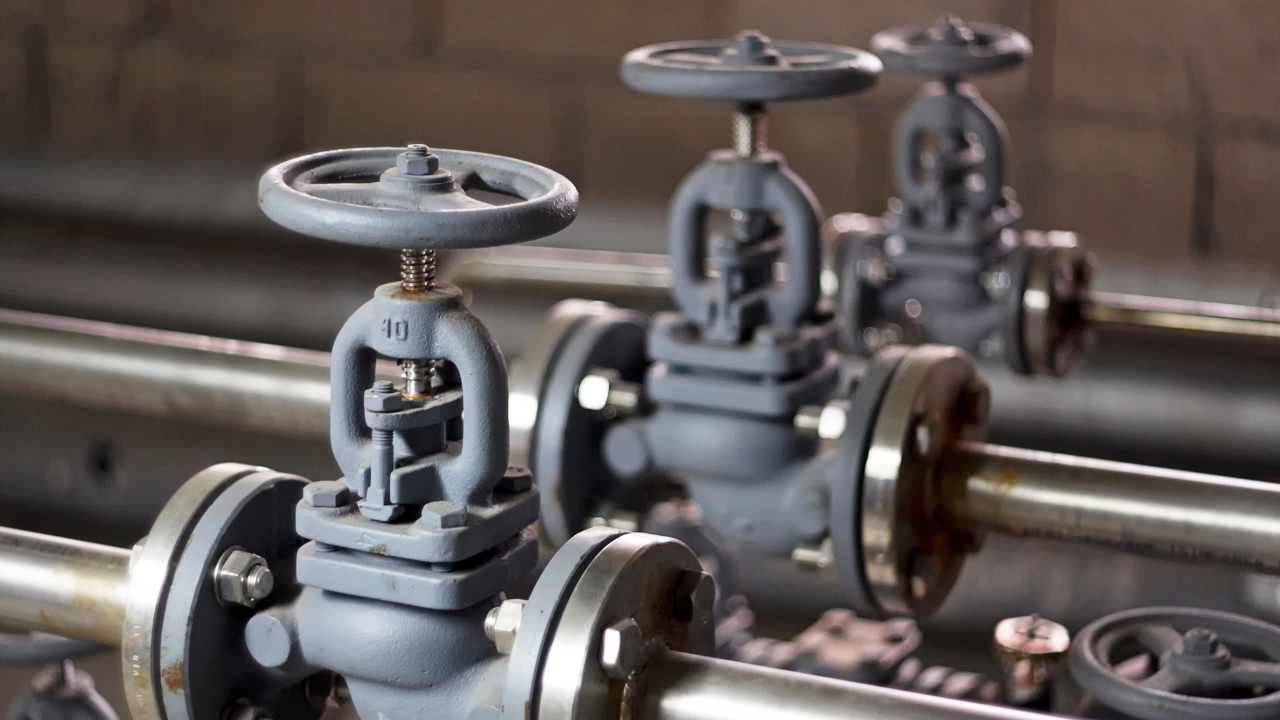

Galvanizing is the process of coating the steel surface with zinc. The zinc layer reduces the risk of corrosion by protecting the steel from moisture and chemicals. Galvanizing is a common protection method for structural elements, pipes and fittings, especially those used in outdoor conditions.

3. Protective Coatings

Paints, epoxy coatings or polymer-based materials applied to the steel surface create an effective barrier against corrosion. These coatings prevent steel from rusting by cutting off its contact with water and oxygen. This method is often preferred in the protection of large steel structures used in industrial facilities.

4. Cathodic Protection

Cathodic protection is an electrochemical method that prevents steel from corroding. In this system, an anode metal bonded to the steel acts as a sacrificial electrode, protecting the steel from corrosion. This method is very effective in the maritime sector and underground pipelines.

5. Adding Alloying Elements

Adding elements such as chromium, nickel, molybdenum and vanadium to the structure of steel can increase the corrosion resistance of the material. Steel types used especially in chemical plants and systems exposed to high temperatures are strengthened with this method.

6. Regular Maintenance and Control

Regular cleaning and checking of steel structures ensures early detection of corrosion. Addressing minor signs of rust can prevent larger problems.

Methods used to extend the durability and life of steel make a big difference in industrial and construction projects. Methods such as stainless steel, galvanizing, protective coatings and cathodic protection increase the resistance of steel to corrosion, making projects cost-effective and reliable. With the right protection methods, steel can serve for many years even in harsh conditions.

News

Let You Be the First to Know about Our News and Announcements.

Your Email Address

.jpg)