- Home

- Properties of Special Steels and Their Use in Industry

Properties of Special Steels and Their Use in Industry

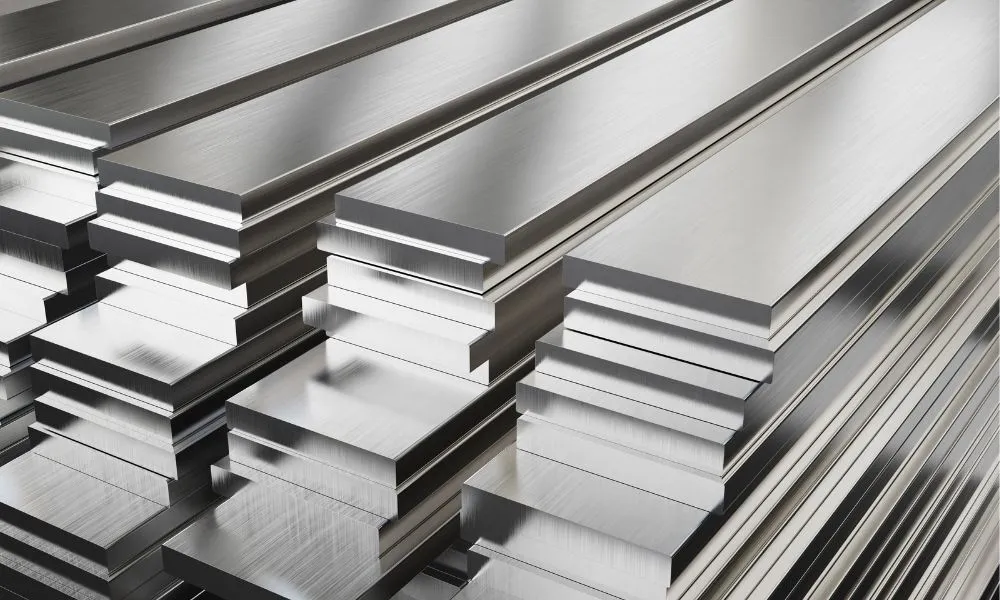

Special steels are types of steels that are specially designed and processed to serve a specific purpose. These steels are used in a wider range in terms of their properties and performance because they have important properties such as high durability, wear resistance, and especially resistance to thermal or chemical conditions. Special steels are generally encountered in types such as carbon steel, alloy steel, and stainless steel, and these types are of great importance in different industrial applications.

The most distinctive feature of special steels is their chemical composition and customizations in production processes. For example, these steels can be strengthened with alloy elements such as carbon, chromium, nickel, and molybdenum in accordance with a specific purpose. In this way, the steel becomes more durable, harder, or more flexible. While high-carbon special steels are preferred in applications requiring hardness and wear resistance, stainless steels are widely used in areas requiring corrosion resistance.

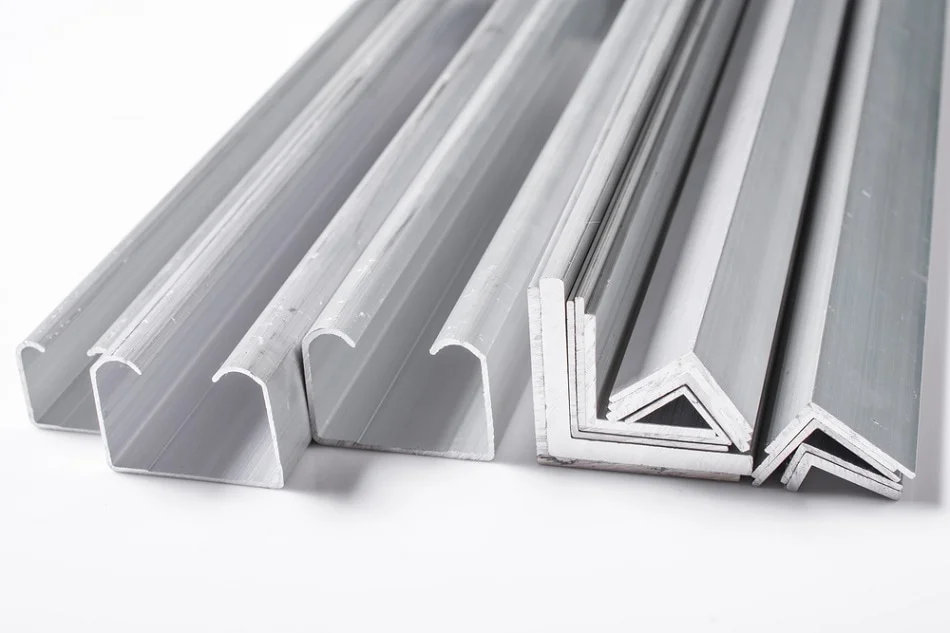

One of the most important areas of use of special steels is the automotive sector. Qualified steels are preferred in automobile engine parts, chassis elements, gears and brake systems. These steels offer long-lasting and safe performance thanks to their high durability and wear resistance. In addition, in the aviation and space industry, qualified steels resistant to high temperatures and harsh environmental conditions are used in a similar way. Here, the lightness and durability of the materials are critical to the safety of aircraft and space vehicles.

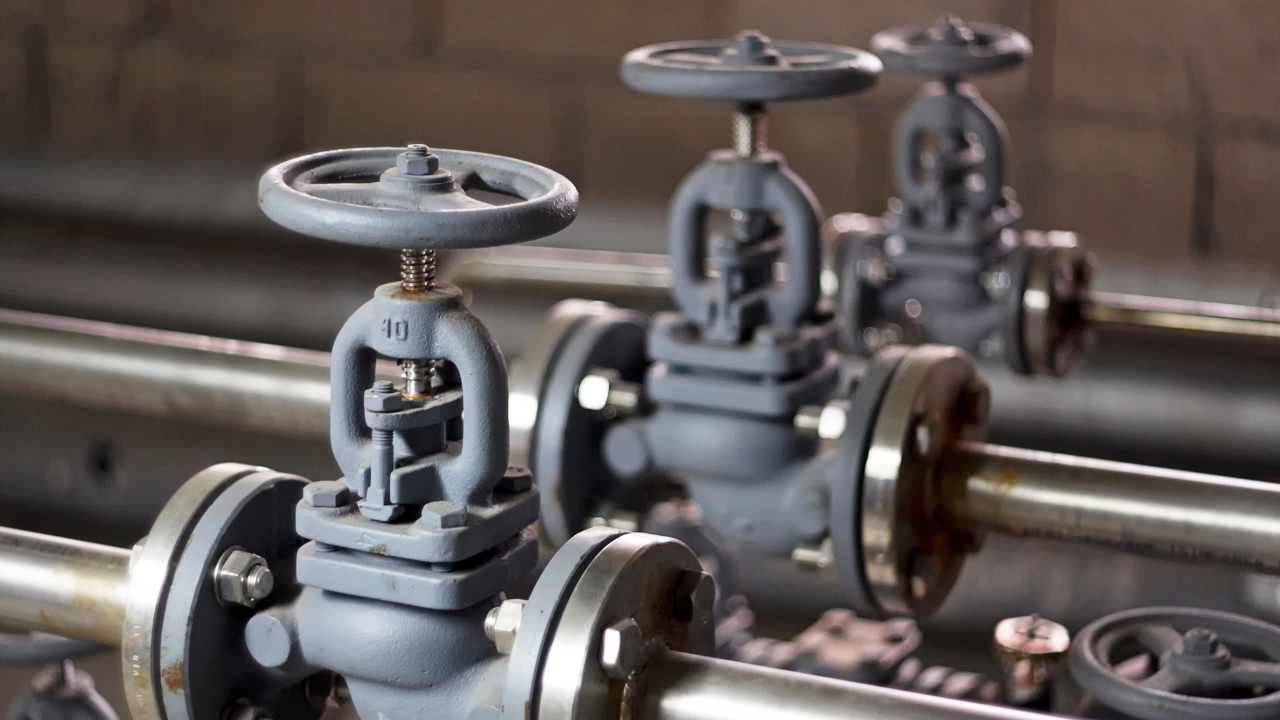

In industrial production processes, qualified steels are used in machines, pumps, turbines and automatic production lines. Such steels can work effectively even in difficult conditions such as excessive load, friction and high speed. In addition, the use of qualified steels is widespread in areas such as the maritime sector, construction sector and energy production. Especially in the maritime sector, steels must be resistant to water salinity and stainless. In power plants, materials resistant to high temperatures and high pressure must be used.

In addition, qualified steels play a critical role in equipment used in chemical processes. In chemical plants, materials resistant to acidic or alkaline substances are required, so stainless steel and alloy steels are often preferred in reactors, pipes and fittings.

As a result, qualified steels play a major role in the creation of high-performance and safe structures in industrial areas. Thanks to their high durability, corrosion resistance and long-lasting performance, these steels are among the indispensable materials in many sectors. With the advancement of technology, the development of more durable and environmentally friendly qualified steel types will increase efficiency in industrial applications.

News

Let You Be the First to Know about Our News and Announcements.

Your Email Address

.jpg)