- Home

- Maintenance of Steel Flanges and Fittings

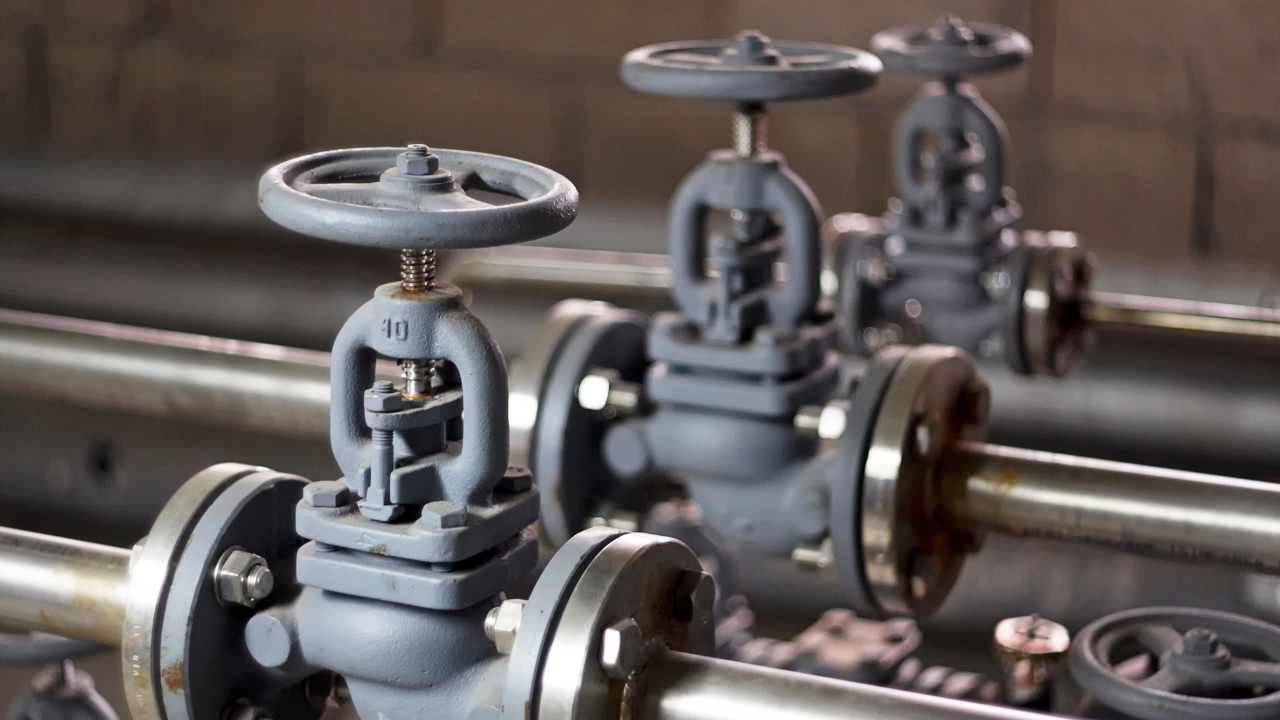

Maintenance of Steel Flanges and Fittings

Steel flanges and fittings used in industrial facilities and infrastructure projects have a critical role in the safety and efficiency of the system. These elements ensure a solid and leak-proof connection of the pipes. However, there is a risk that these parts may lose their functionality over time due to wear, corrosion or other environmental effects. Regular maintenance and correct applications ensure that steel flanges and fittings have long life and optimum performance.

Maintenance Highlights

- Regular Inspection: Detect problems such as cracks, rust or deformation early with visual inspections.

- Cleaning: Removing rust and dirt improves sealing performance.

- Leak Check: Prevent the risk of leaks by replacing worn seals.

- Torque Adjustment: Tighten the flange screws to the correct torque; Over- or under-tightening may cause problems.

- Protective Coating: Prevent corrosion with galvanizing or epoxy coating.

- Periodic Tests: Evaluate system performance with pressure and leakage tests.

Regular maintenance reduces costs, extends system life and increases occupational safety. These measures are of vital importance, especially in the petrochemical, energy and construction sectors. You can guarantee safety and efficiency in your projects by adhering to the maintenance schedule.

News

Let You Be the First to Know about Our News and Announcements.

Your Email Address

.jpg)