- Home

- Selection of High Quality Rebar

Selection of High Quality Rebar

The solid and reliable structure of construction projects is directly dependent on the quality of the materials used. Reinforced iron stands out as one of the most critical components among these materials. The durability of reinforced concrete structures is directly related to the mechanical properties of the rebar and its correct selection. Choosing high-quality rebar not only ensures the longevity of structures, but also provides resistance to natural disasters and heavy load conditions.

The first factor to consider when choosing quality rebar is the rebar's compliance with standards. It is of great importance in terms of structural safety that the rebars are produced in accordance with national and international standards. These standards determine the chemical composition, tensile strength and flexibility properties of the rebar. In particular, compliance with standards such as TS 708 and EN 10080 should be checked. These standards guarantee that the rebars can be used safely in earthquake-resistant structures.

Another important criterion is the chemical composition of the rebar. High-quality rebar should have a certain ratio of carbon, manganese, sulfur and phosphorus. The amount of carbon increases the strength of the iron, while excessively high carbon levels can reduce flexibility and lead to brittleness. Therefore, a suitable carbon rate ensures that the iron is both strong and flexible in a balanced way.

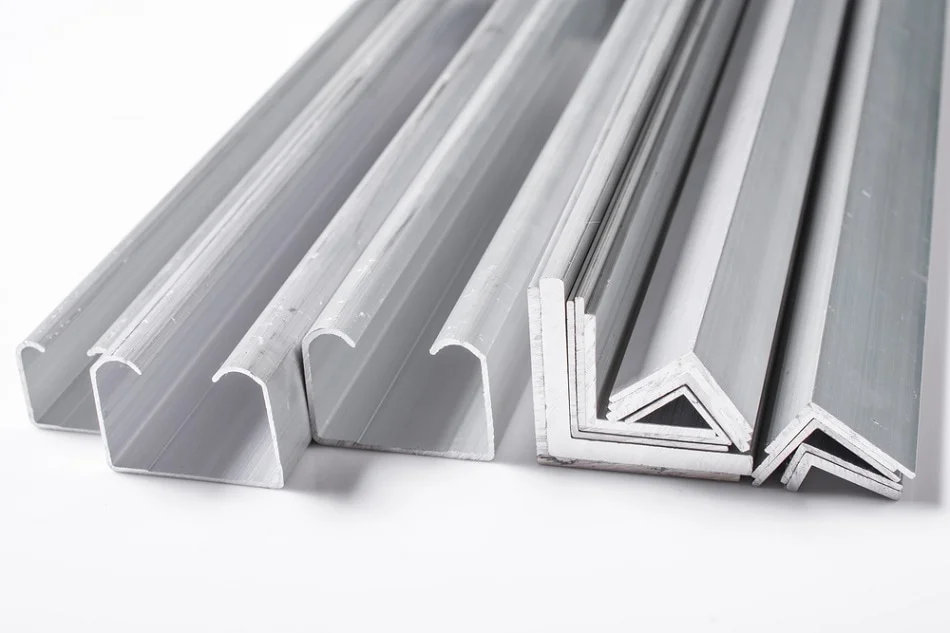

The surface shape of the iron is also one of the factors that determine its quality. Ribbed irons increase the load-carrying capacity of structures by establishing a stronger bond with the concrete. This bond is especially important in areas exposed to seismic movements, because the ribbed structure protects structural integrity by preventing the concrete from cracking. Flat-surface irons, on the other hand, offer less binding properties and are generally used in special projects.

The reliability of the supplier also plays a critical role when choosing quality rebar. The factories where the irons are produced should be supplied from certified manufacturers who care about quality control processes. This attention in the supply chain ensures that the project progresses smoothly and prevents unexpected material problems.

Finally, environmental conditions and project requirements should also be taken into account when choosing rebar. For example, in regions with high humidity, stainless coating or special corrosion-resistant irons should be preferred. This type of iron maintains its durability for many years, reducing maintenance and repair costs.

Choosing high-quality rebar is indispensable not only for the durability of the structure, but also for the economic efficiency and long-term success of the project. The right choices both increase safety and ensure the sustainability of the projects.

News

Let You Be the First to Know about Our News and Announcements.

Your Email Address

.jpg)